Seals for industrial strapping are essential components that ensure the security and stability of strapped loads during handling, transport, and storage. These small but crucial items are used to fasten steel or plastic strapping, holding it firmly in place once tensioned. Various types are available, including open, closed, and pusher seals, each suited to specific tools and applications. The correct choice of seal depends on factors such as strapping width, thickness, and the nature of the load. In high-tension applications, such as securing heavy pallets or bundling construction materials, seals must offer high resistance to slippage and breakage. Steel seals are typically used with steel strapping, while serrated seals are preferred with polyester strapping for better grip. A properly crimped seal enhances safety and minimises product damage by preventing strap loosening. In any industrial setting, using the right seal is vital for maintaining load integrity and operational efficiency.

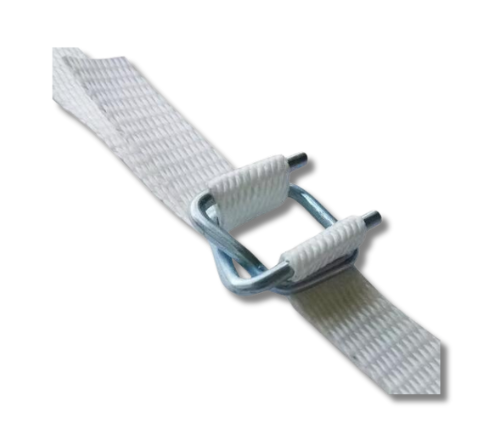

Buckles for industrial strapping play a key role in securing loads safely and efficiently, particularly in applications where flexibility and reusability are important. Unlike seals, which are crimped into place, buckles allow the strap to be manually tensioned and adjusted without specialised tools. This makes them ideal for lighter loads or situations where strapping needs to be applied and removed frequently. Commonly used with Woven Polyester (not PP or PET) buckles, plastic buckles, and heavy-duty metal variants. Their design typically features a strong grip that holds the strap securely in place through friction and tension. Wire buckles, often galvanised, are especially popular due to their strength and weather resistance. Correct use ensures a tight, reliable hold that adapts slightly under strain, helping to absorb shock during transit. Buckles are a practical and cost-effective option for a wide range of packaging and shipping needs.