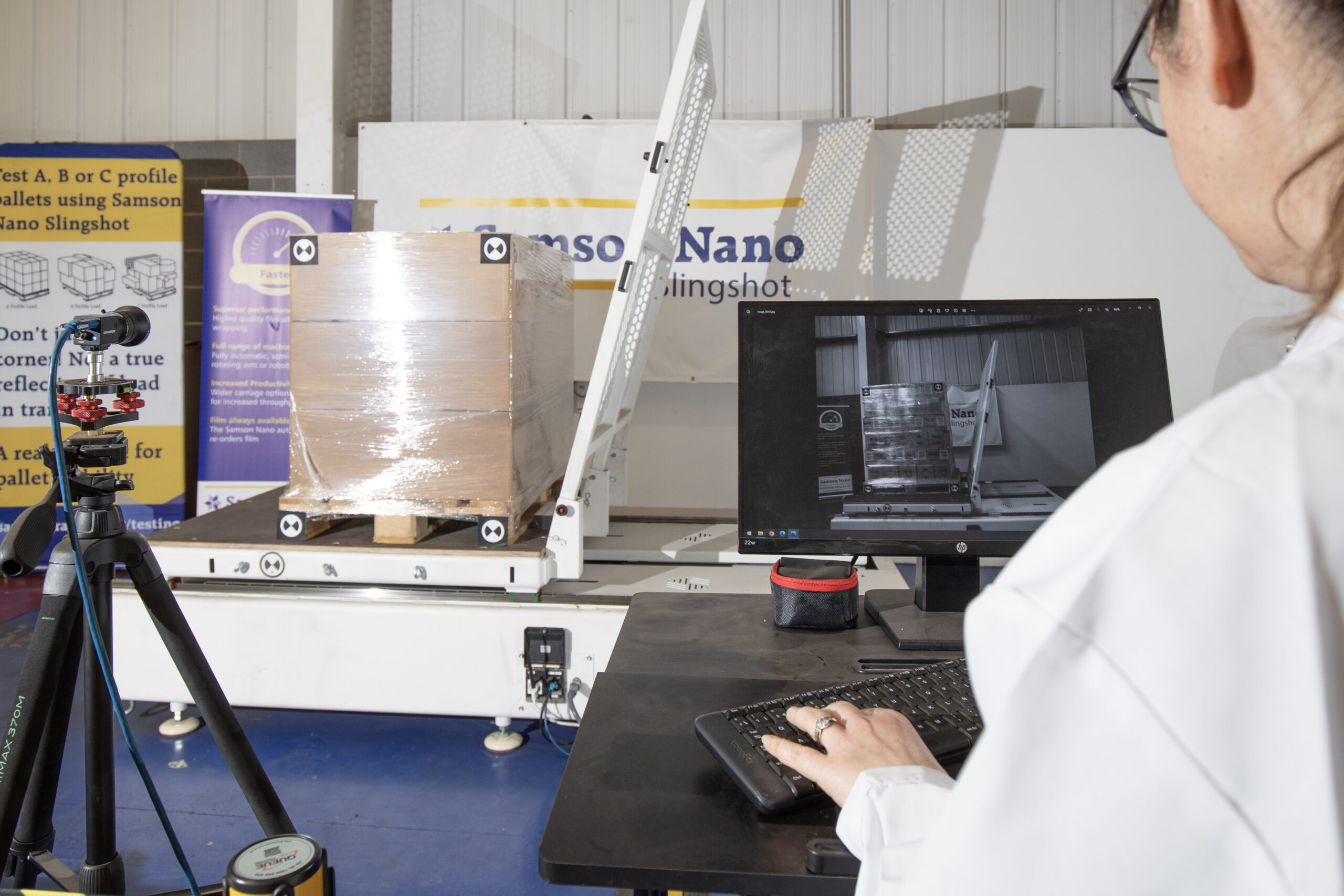

The Slingshot is the first of its kind to be installed in the UK and unique to Samson Pallet Stability. The Samson Nano Slingshot is a horizontal pallet testing table that replicates the inertia of a vehicle and ascertains whether the load will potentially displace in transit. The machine initially tests at 0.1G and works up to the EUMOS standard of 0.8G. From the pallet data entered, the maximum deformation of the load is calculated to create a pass or fail. If a pallet fails the test, the wrapping process is adjusted until a pass is received. This gives clients reassurance that their goods will arrive safely and securely.

Pallet stability and safety are crucial to manufacturers, who not only want their goods to reach their destination in perfect condition, but also need to keep their warehouse teams, logistics operators and the wider public safe from displaced loads. The cost of a displaced load can sometimes be more than the cost of the goods themselves, and manufacturers can be at risk of logistics operators refusing to take their goods if health and safety concerns arise for operators.

EUMOS

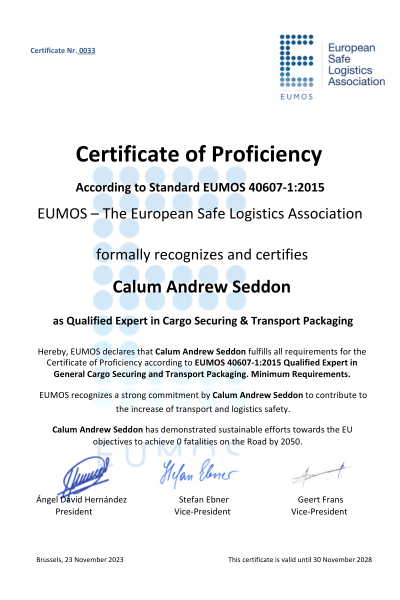

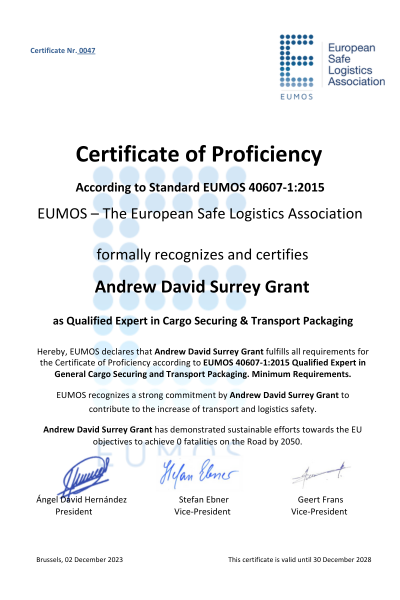

EUMOS is the European Safe Logistics Association, of which Samson Pallet Stability are proud members. EUMOS are aiming to reduce the number of fatalities to Zero by 2050 instilling safer working practices throughout the supply chain and have created standards which are industry recognised.

By using the Samson Nano Slingshot, customers can guarantee compliance with the EUMOS:40509 2020 safety standards.

Strapping Breakload Testing

Our Strapping Breakload Testing machine measures the efficiency of strapping, by stretching the strap to its breaking point. This allows us to compare the breaking point to the weight of the goods being palletised and recommend the optimum strapping solution to ensure safe and secure transit. For further peace of mind, once the correct strapping solution has been applied, customers can test the pallets on the Slingshot to EUMOS standards.

Stretch Film Analysis

Unwind machine information

Highlight Industries, based in the USA, has been the global leader in stretchfilm testing solutions for over two decades. Their equipment is designed to accurately and reliably measure the length of stretchfilm rolls, ensuring precision in packaging and quality control.

The unwind testing capabilities include high-speed performance, with the ability to test at rates of up to 150 metres per minute. This allows for efficient and rapid evaluation of stretchfilm performance.

The Highlight LMS-1000 exemplifies the company’s ongoing commitment to producing high-quality testing equipment, combining advanced technology with durable design to meet the needs of modern packaging operations.